We like to get the opportunity to thank Mike Buetow president of PCEA for enabling us to generally be part in their podcast. We talked about the origins of our business, the merchandise, services, and the process that have manufactured us productive. We hope you’ll sign up for the podcast.

In spite of suitable planning and procedure, soldering challenges can even now crop up. Here are a few prevalent issues and their prospective methods:

Use a gentle steel pipe brush to clean the area wherever they overlap and apply a flux paste alongside any outdated joints that will happen to be weakened or corroded.

Remedy: If you will discover gaps from the solder you must include much more solder to the realm and reapply warmth until the gaps are stuffed.

Typically obtainable solders involve tender lead solder, silver solder, copper phosphorus silver solder, metal pipe flux cored wire and non-corrosive fluxes. To decide which form is most appropriate for your radiator repair, study through this manual:

If your car has a radiator leak you might be wanting to know what sort of solder to utilize on radiator mend. The solution is determined by the material of your radiator and the amount of leak.For little leaks You should use a soft solder such as guide-no cost solder.

Aluminum is among the more prevalent components Utilized in automotive radiators nowadays. Aluminum radiators are potent and light, they don't corrode or plug up like copper and brass radiators and aluminum dissipates warmth competently. Aluminum radiators are also more robust and lighter than copper and brass radiators. Aluminum radiators can make the most of a thinner core, with broader tubes, allowing for for much better air and coolant movement through the radiator.

Little by little do the job your way down the crack right until it is completely covered with solder. Make sure to unplug the iron if you find yourself done soldering, mainly because most usually do not convert off by on their own.

Take away the excess flux and oxide. When you are utilizing a h2o-dependent flux, the flux can be rinsed off with h2o after the concluded piece has cooled.

Most of all, make certain that the region is properly ventilated as it could be uncomplicated to be confused by fumes.

Solder the harmed region entirely. Make use of a high-wattage soldering iron and very thick soldering wire. Warmth the gun extensively so that the solder melts well and bonds Using the surface area in the radiator. Warmth the harmed part of the radiator Together with the soldering iron and introduce the wire bit by bit, seeking never to drip solder in to the radiator alone.

Grind the solder occupation so there are no burrs or sharp edges. This can be carried out with a little wheel or wire brush. The thought is to produce click over here the solder line as sleek as is possible and remove any contaminants.

Employing our proprietary engineering, we transform these byproducts into the best-purity Electrolytic Solder

As a result, it is essential to receive appropriate training, adhere to manufacturer's rules, and adhere to safety regulations and techniques. WikiHow and Jones Welding & Industrial Provide, Full Article Inc usually do not believe any accountability or liability for any injuries, damages, or losses resulting within the use or misuse of the data presented. Generally request Experienced assistance and consider acceptable safety measures to make sure your basic safety when partaking in welding activities. You are able to often seek advice from with your neighborhood welding provide keep for being led into the ideal direction!"

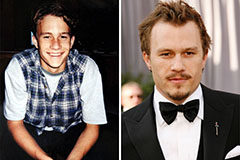

Heath Ledger Then & Now!

Heath Ledger Then & Now! Sydney Simpson Then & Now!

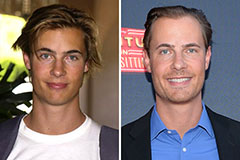

Sydney Simpson Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now!